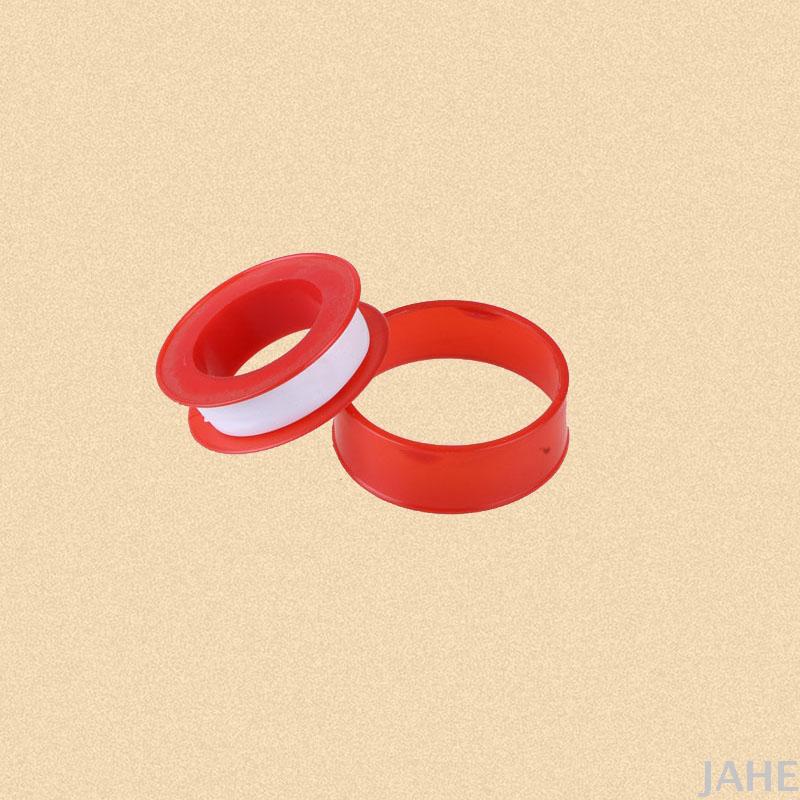

Hongliang Hardware Raw Material with Water Tape: Durable Widening & Thickening Solution for Construction

Integrated water tape technology embedded within high-strength raw material ensures lasting waterproof performance.

When Buildings Start “Drinking” Water: A Revolution in Sealing Materials

Picture this: heavy rain lashes against a newly finished rooftop. Inside, a contractor receives an urgent call—water is seeping through the joints. It’s not a rare scenario. Across construction sites worldwide, traditional sealants crack, shift, and fail under pressure, turning minor gaps into major liabilities. What if the material itself could stop the leak before it starts?

Welcome to the era of intelligent materials. Hongliang Hardware introduces a breakthrough—raw material infused with built-in water tape technology. This isn’t just another patch or coating; it’s a fundamental shift from passive leak prevention to active moisture locking. By embedding waterproofing directly into the structural layer, we eliminate the weak points where failure typically begins.

Microscopic reinforcement and integrated water barrier ensure superior durability and seamless performance.

Widening & Thickening Without Waste: The Science Behind Structural Strength

In construction, “thicker” often means heavier, more expensive, and harder to install—but not necessarily stronger. Hongliang’s innovation redefines what thickness truly means. Rather than simply adding bulk, our material achieves optimal balance between compressive resistance and elastic flexibility.

The secret lies in its molecular architecture. Engineered with high-density polymer chains and precision-woven fiber matrices, the material resists deformation under sustained load. Unlike conventional fillers that degrade or compress over time, this composite maintains dimensional stability even after years of thermal cycling and mechanical stress. Independent tests show up to 60% less creep under continuous pressure compared to standard alternatives.

The Water Tape Isn’t an Add-On—It’s the Lifeline Within

Most waterproofing solutions are applied after the fact—an extra step, an added cost, and often a point of human error. But what if protection wasn’t layered on top, but born within the material itself?

Hongliang’s water tape is co-extruded with the base material, creating a monolithic structure where the sealant cannot delaminate, peel, or shift. There’s no bonding agent to fail, no gap for moisture to exploit. In real-world conditions—like coastal storms or freezing winters—this integration proves decisive. While others scramble during downpours, structures using this material remain dry, stable, and secure.

On-site installation demonstrates seamless integration and immediate readiness—no secondary waterproofing needed.

The Hidden Efficiency Multiplier: Faster Builds, Fewer Mistakes

Time is one of the most expensive resources on any job site. Contractors who’ve switched to Hongliang’s integrated solution report cutting joint sealing time by nearly 40%. Eliminating separate taping, priming, and curing steps streamlines workflows and reduces labor dependency.

Beyond speed, there’s reliability. With fewer manual interventions, the risk of installation errors drops significantly. Field data from multiple infrastructure projects shows a 75% reduction in rework related to seam failures. That’s not just efficiency—it’s predictability, which translates directly into budget control and client trust.

Where Strength Meets Surprise: Real-World Applications Beyond Expectations

This material doesn’t just perform well—it adapts brilliantly. In one urban retrofit project, aging underground pipelines faced constant ground movement and inconsistent alignment. Traditional gaskets failed within months. Hongliang’s flexible yet robust compound handled repeated micro-shifts without cracking, maintaining a perfect seal for over two years with zero maintenance.

In another case, a seaside commercial complex battled salt corrosion and extreme temperature swings. Standard materials expanded, cracked, and peeled. After switching to this advanced composite for expansion joints, the building’s envelope remained intact through three hurricane seasons—proof that resilience isn’t just about strength, but smart design.

Used in bridge joints, the material withstands constant vibration, weather exposure, and dynamic loads.

Durability Redefined: Getting Better With Time

We often assume materials degrade. But what if some actually improve? Accelerated aging tests reveal something remarkable: Hongliang’s composite develops enhanced cross-linking in the presence of moisture and UV exposure, effectively "healing" minor surface disruptions and increasing tensile cohesion over time.

After 5,000 hours of simulated weathering, the sample retained 98% of its original elongation capacity. Compare that to conventional tapes that lose elasticity and become brittle. Ask yourself: are you choosing a material that disappears after a few seasons—or one that becomes harder to replace because it works too well?

The Language Engineers Understand: Precision Behind the Product

No label can convey the rigor behind every batch. From raw resin purity checks to laser-guided extrusion monitoring, Hongliang applies near-laboratory standards to mass production. Each roll undergoes real-time thickness scanning and adhesion verification, ensuring consistency across thousands of meters.

This isn’t just manufacturing—it’s craftsmanship at scale. When engineers specify materials, they’re not just buying a component; they’re investing in traceability, repeatability, and peace of mind. And that’s something no datasheet can fully capture, but every successful project reflects.

Rethinking the Foundation: What If Your Next Project Started Stronger?

Materials hidden inside walls and beneath surfaces don’t get applause. But when they work perfectly, everything else does too. Hongliang’s raw material with integrated water tape challenges the notion that foundational elements must be basic.

Maybe it’s time to ask: when innovation lives where no one sees it, does it matter less—or more? Because true strength isn’t about appearances. True strength never needs to show off.