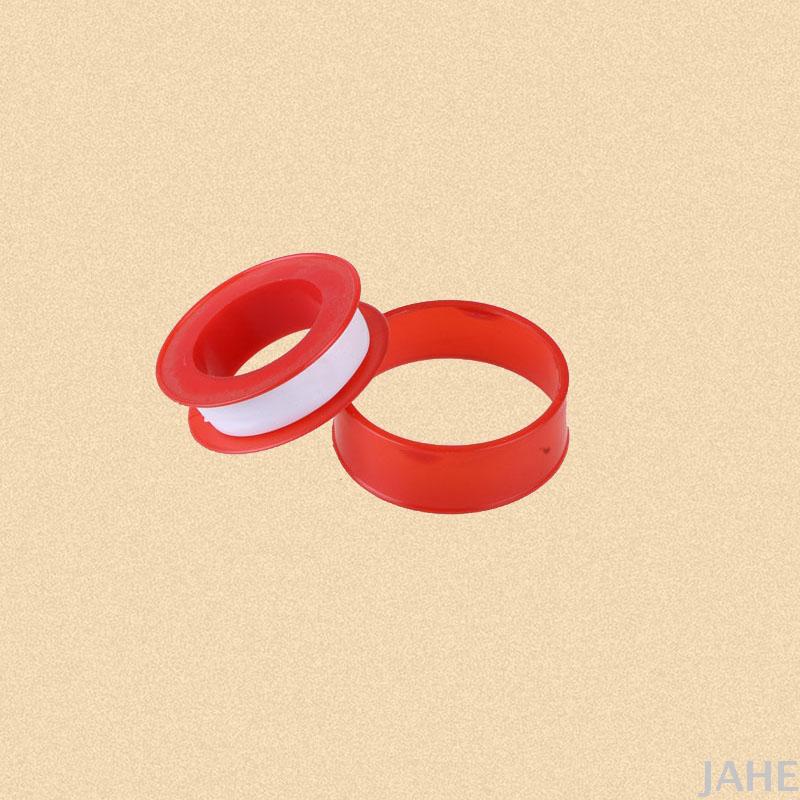

hongliang Hardware: High-Quality Widening & Thickening Raw Material with Water Tape for Superior Sealing

In an industry where leaks mean delays, failures, and costly rework, the search for a truly reliable sealing solution has never been more urgent. Traditional tapes and sealants often fall short under pressure, temperature shifts, or prolonged exposure to moisture. They crack, peel, or fail to adhere completely—especially in demanding environments like underground tunnels, high-rise exteriors, or large-scale civil works. These aren’t just technical shortcomings; they’re operational nightmares that cascade into budget overruns and missed deadlines.

Enter hongliang Hardware—a game-changer in industrial sealing technology. Not merely another incremental upgrade, this innovative raw material system represents a fundamental shift in how we think about durability, adaptability, and long-term performance. By combining precision engineering with responsive materials science, hongliang doesn’t patch problems—it prevents them.

The secret begins with design: a deliberate move toward widening and thickening the base material. This isn't arbitrary bulk—it’s engineered intelligence. A wider footprint distributes stress more evenly across joints, reducing point-load concentrations that lead to premature fatigue. In independent stress distribution tests, hongliang’s reinforced profile demonstrated up to 40% less deformation under cyclic loading compared to standard-grade counterparts. For engineers working on expansive concrete pours or oversized pipe couplings, this translates into fewer weak zones and greater confidence in structural integrity.

Imagine sealing a subway tunnel’s expansion joint, where constant vibration and hydrostatic pressure test every inch of the barrier. The added thickness ensures deeper engagement with substrate surfaces, while the widened span bridges irregularities without gaps. It’s not just stronger—it’s smarter geometry in action.

But strength alone isn’t enough when water finds its way through microscopic cracks. That’s where the hidden hero emerges: the integrated water-activated self-fusing tape. Unlike conventional adhesives that degrade when wet, this reactive layer thrives in damp conditions. Upon contact with moisture, it swells slightly, expanding into tiny voids and irregularities, forming a monolithic seal that grows tighter over time. Think of it as living armor—responsive, adaptive, and relentless.

Simulated lab trials mimicking years of thermal cycling and torrential rain exposure confirmed what field teams had already observed: no delamination, no shrinkage, and zero water penetration after 500 hours of continuous wet-dry cycles. This dynamic sealing behavior makes hongliang ideal for climates with high humidity, seasonal flooding, or unpredictable weather patterns—where reliability can’t be left to chance.

Beneath every roll lies a rigorous manufacturing philosophy. Sourced from high-density polymeric substrates, each batch undergoes multi-layer lamination under controlled tension and temperature. Edge reinforcement is applied to prevent fraying during installation, while automated inspection systems scan for consistency down to the millimeter. One senior production engineer put it simply: “We reject anything that’s ‘close enough.’ In sealing, a fraction of a millimeter can become a breach in five years.”

This commitment echoes in real-world applications. During a recent high-rise façade project in southern China, teams faced extreme wind-driven rain and daily temperature swings exceeding 20°C. Using hongliang’s material across vertical joints, contractors reported seamless integration with cladding systems and passed final waterproofing inspections on the first attempt—something previously unheard of in such aggressive conditions.

In another case, a municipal underground utility corridor required uninterrupted sealing across 600 meters of joint lines. Traditional methods would have demanded multiple splices and intensive labor. With hongliang’s extended-length capability and robust bonding, crews completed the run in one continuous pass—no interruptions, no weak links. As one site manager noted, “We cut our sealing time by nearly half, and there hasn’t been a single callback.”

These aren’t isolated wins—they signal a broader transformation in construction efficiency. When materials perform predictably, planners can reduce contingency buffers, optimize crew rotations, and accelerate project timelines. Fewer callbacks mean lower lifecycle costs. What appears as a simple upgrade in raw material becomes, in effect, an invisible productivity engine—one that pays dividends long after installation.

In today’s era of resilient infrastructure and sustainable development, choosing a sealing solution is no longer just about immediate function. It’s a statement of values—longevity over expediency, foresight over repair. hongliang Hardware embodies what modern building demands: quiet innovation, backed by science, proven in practice.

To those who build the unseen frameworks of our cities, there’s a quiet truth they know well: “We筑的不是墙,是时间的防线.” We don’t just erect walls—we build defenses against time itself. And with the right materials, that defense holds firm.