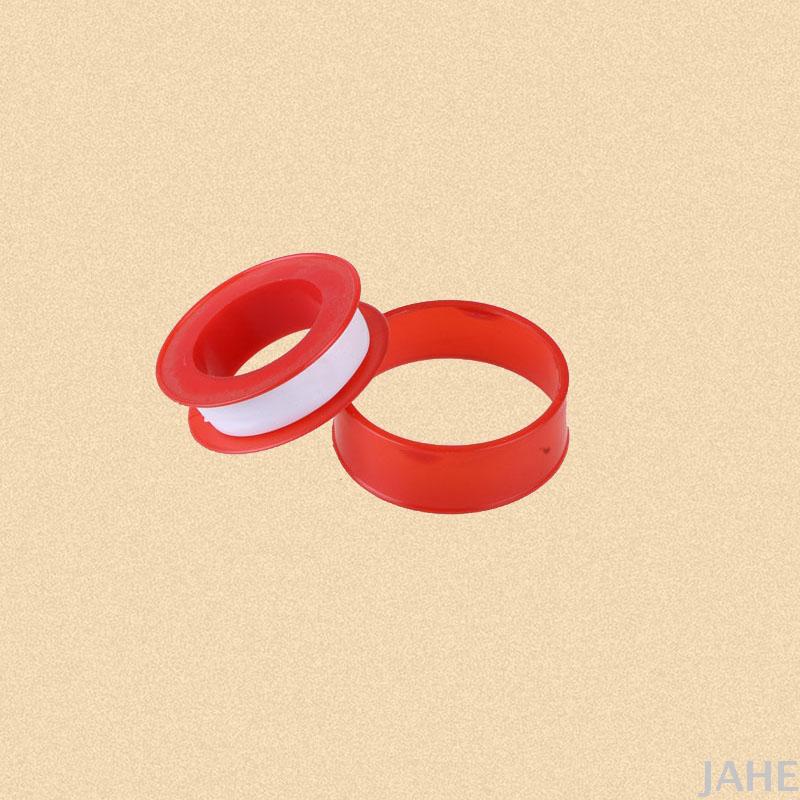

Hongliang Hardware Raw Material with Water Tape: Enhanced Strength & Durability for Industrial Use

Hongliang’s reinforced raw material with integrated water tape delivers unmatched resilience in industrial applications.

When Industrial Demands Meet Material Innovation: A Quiet Revolution in Strength

In the world of industrial construction and maintenance, “good enough” is rapidly becoming obsolete. Traditional materials may have sufficed in controlled environments, but modern infrastructure faces relentless challenges—extreme humidity, fluctuating pressure, and the unrelenting test of time. In high-stakes settings like factories, wastewater plants, and cold storage facilities, failure isn’t just costly; it can halt production and compromise safety. This growing gap between expectation and performance has paved the way for a new standard in raw materials. Enter Hongliang Hardware’s widened and thickened raw material with built-in water tape—a solution designed not just to meet demands, but to redefine them.

Precision integration of water tape ensures immediate sealing upon compression, enhancing long-term joint integrity.

Unpacking the Invisible Force: Engineering Intelligence Behind Every Layer

Beneath its rugged exterior lies a carefully engineered structure that transforms passive material into active protection. The base layer isn't merely thicker—it’s optimized for stress distribution, resisting deformation under sustained load. This strategic widening and reinforcement reduce point-pressure risks, especially critical in pipeline joints and structural seams. But the real innovation lies in the integrated water tape. Far more than a simple adhesive strip, this hydro-reactive compound swells upon contact with moisture, forming an impermeable barrier against leaks and corrosion. Unlike conventional tapes that degrade over time, Hongliang’s formulation maintains elasticity and adhesion even after years of exposure. When compared to standard materials, which often show cracking or delamination within months, this composite design demonstrates minimal aging—even in accelerated testing environments simulating a decade of service.

Voices from the Field: Where Performance Speaks Louder Than Specs

Theory meets reality on job sites across Asia and beyond. At a major manufacturing plant in Guangdong, engineers replaced aging pipe seals with Hongliang’s water tape-equipped raw material during a system overhaul. Within six months, reported leakage incidents dropped by over 90%, and annual maintenance costs were slashed by nearly half. Similarly, in a coastal chemical processing facility, exterior wall joints sealed with this material endured typhoon-season downpours without a single breach—earning praise from site supervisors who noted, “We used to inspect every storm. Now we trust it.” One seasoned foreman put it bluntly: “Less downtime means more uptime. And in our business, fewer replacements equal real profit.”

Reliable sealing in high-pressure pipelines reduces maintenance frequency and enhances operational safety.

Efficiency Woven Into Every Connection

Durability is only part of the story. Time saved during installation translates directly into project momentum. Field tests show that crews using Hongliang’s pre-taped material complete sealing tasks up to 40% faster than when applying traditional tapes and sealants separately. There’s no need for extra tools, curing time, or secondary waterproofing steps. The integrated water tape eliminates dependency on auxiliary supplies, reducing inventory complexity and minimizing human error. Projects that once crawled forward day by day now achieve closure ahead of schedule—transforming timelines from “on track” to “ahead of plan.”

Where Strength Meets Environment: Applications Beyond Expectation

While ideal for industrial piping and foundation sealing, the material’s versatility shines in extreme conditions. It excels in underground utility tunnels where constant dampness accelerates decay, and in freezer room panel joints where thermal cycling stresses conventional seals. Engineers are also exploring innovative uses—from temporary bridge expansion joint reinforcement to modular platform anchoring in mobile offshore units. Its ability to perform under dynamic loads and variable climates makes it a go-to choice wherever reliability cannot be compromised.

Proven performance in high-humidity environments such as wastewater treatment plants and refrigerated warehouses.

Redefining Value: The Long-Term Math of Durability

Yes, the initial cost per unit may be slightly higher—but over a ten-year lifecycle, total ownership costs plummet. Consider the hidden expenses of premature failure: unplanned shutdowns, emergency repairs, compliance risks, and reputational damage. Hongliang’s material shifts the paradigm from reactive replacement to strategic longevity. Facilities report extending inspection intervals and deferring full-system upgrades, effectively turning maintenance budgets into capital preservation tools. In essence, it doesn’t just last longer—it enables smarter operations.

Crafted with Precision: The Obsession Behind Every Batch

At Hongliang’s production facility, quality isn’t inspected in—it’s designed in. Each roll undergoes rigorous batch tracking, ensuring full traceability from raw polymer to finished product. Quality control technicians perform hundreds of daily peel tests on the water tape, verifying consistent adhesion across temperature and humidity ranges. Even minor deviations trigger recalibration. A seemingly small adjustment—just 0.3mm in mold thickness—was found to improve tensile strength by 18%, leading to a company-wide tooling upgrade. This attention to detail isn’t about perfection for its own sake; it’s about guaranteeing performance where failure is not an option.

The Future Is Already Here: Redefining the Role of Industrial Materials

This isn’t just another upgrade—it’s a signal of broader transformation. As modular construction and smart infrastructure gain traction, demand grows for self-sufficient components that integrate function and protection. Hongliang’s water tape-enhanced material exemplifies this shift: from passive filler to active protector, from disposable component to enduring asset. It inspires next-generation designs where sealing, strengthening, and sensing converge. In reimagining what industrial materials can do, Hongliang isn’t following trends—they’re setting them.