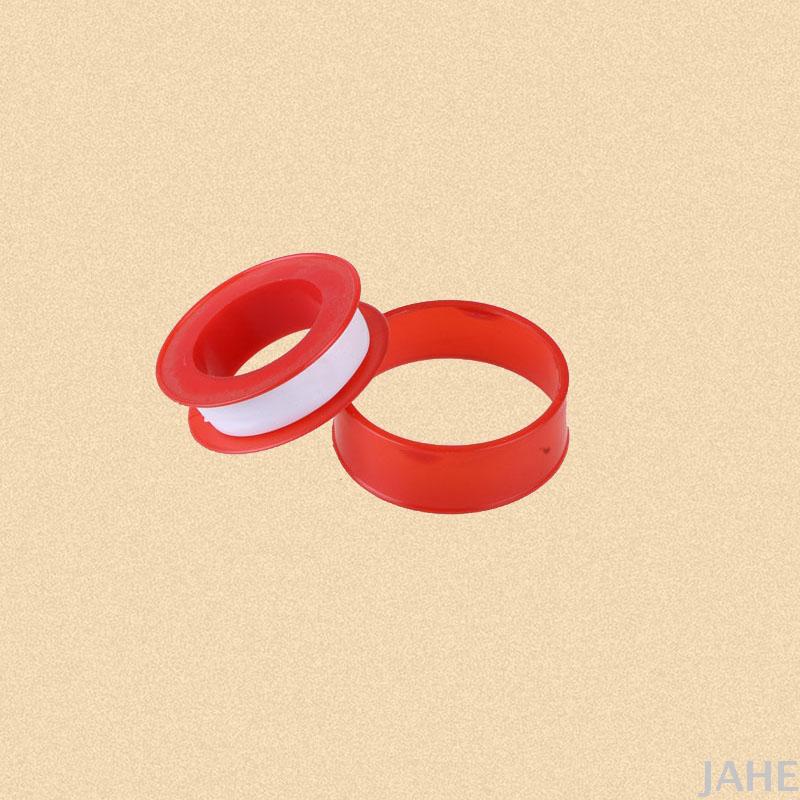

In the world of construction and industrial manufacturing, materials must do more than just hold their shape—they need to adapt, expand, and endure. Whether sealing gaps in concrete structures or reinforcing pipe joints, the right material can make the difference between a temporary fix and a long-term solution. This is where Hongliang Hardware steps in, offering a unique approach to material engineering that combines flexibility with resilience. At the heart of this innovation lies a remarkable component: water tape.

When Strength Meets Flexibility: The Secret Behind High-Performance Materials

In modern construction, materials are often subjected to extreme conditions—temperature fluctuations, moisture exposure, and structural movement. Traditional materials may crack, warp, or lose adhesion over time. Hongliang Hardware recognized this challenge and developed a line of raw materials designed to not only withstand these stresses but also enhance performance through controlled widening and thickening. By integrating water tape into their formulations, they've achieved a balance between strength and elasticity that sets a new standard for durability.

The Evolution of Widening and Thickening Techniques in Modern Manufacturing

Historically, widening and thickening materials relied on heavy additives or mechanical expansion, which often compromised the integrity of the base material. These methods could lead to inconsistent results and longer curing times. In contrast, Hongliang’s approach leverages advanced polymer science and the natural properties of water tape to create a seamless expansion process. This ensures that materials retain their core strength while adapting to dynamic environments with ease.

What Makes Water Tape a Game-Changer in Material Application?

Water tape is not just a binding agent—it’s a performance enhancer. When exposed to moisture, it expands slightly, filling gaps and creating a tight, durable seal. This characteristic is especially valuable in applications where expansion and contraction are frequent. When combined with Hongliang’s proprietary raw materials, the result is a composite that is not only more robust but also more responsive to environmental changes. The synergy between water tape and high-performance polymers allows for controlled thickening and uniform widening, ensuring optimal coverage and long-lasting results.

Inside the Lab: How Hongliang Tests and Perfects Its Raw Materials

Behind every Hongliang product is a rigorous testing process. Their research team conducts extensive trials to evaluate how materials behave under pressure, moisture, and varying temperatures. Each batch is tested for expansion rate, adhesion strength, and drying time. These tests ensure that only the highest quality materials reach the market. The brand’s commitment to continuous improvement means that their products evolve alongside the needs of the industry, always staying ahead of the curve.

From Factory to Field: Real-World Applications of Widened and Thickened Materials

The true test of any material is how it performs in real-world conditions. Hongliang’s widened and thickened raw materials have been successfully deployed in a variety of applications—from sealing expansion joints in commercial buildings to waterproofing underground pipelines. Contractors and engineers praise the material’s ease of use, reliability, and longevity. One standout example is a large-scale infrastructure project where Hongliang’s water tape-infused material was used to seal a concrete tunnel. The result? A leak-proof, durable seal that required minimal maintenance over the following years.

Why Precision Matters: How the Right Material Thickness Impacts Project Success

Thickness is not just about bulk—it's about performance. Too thin, and the material may not provide sufficient coverage or strength. Too thick, and it may become rigid and difficult to apply. Hongliang understands this delicate balance and has engineered its materials to achieve optimal thickness through precise formulation. This ensures that every application delivers consistent results, whether it's used in residential construction or large industrial facilities.

Behind the Scenes: The Craftsmanship That Sets Hongliang Apart

What makes Hongliang stand out is not just the technology, but the philosophy behind it. Every stage of production—from sourcing raw materials to final packaging—is handled with meticulous care. The brand blends traditional craftsmanship with modern innovation, ensuring that every product is not only functional but also reliable. This commitment to excellence has earned Hongliang the trust of professionals worldwide, from architects to civil engineers.

Choosing the Right Material for Your Needs: A Quick Guide

Not all projects are the same, and neither are the materials used. For high-movement areas like expansion joints, a material with superior elasticity and controlled widening is essential. In contrast, static applications may benefit more from increased thickness and structural rigidity. Hongliang offers a range of products tailored to different needs, allowing users to select the right solution for their specific conditions. Always consider the environment, expected movement, and desired lifespan of the application when choosing materials.

The Future of Material Engineering: Where Is Hongliang Heading Next?

As the world moves toward more sustainable and intelligent construction practices, Hongliang is already exploring the next frontier. The brand is investing in eco-friendly formulations and researching smart materials that respond to environmental cues. From self-healing composites to biodegradable alternatives, the future of material engineering is promising—and Hongliang is leading the way. Their vision is clear: to build a safer, more adaptable world through smarter materials.